Continuing with the theme of Volumetric Weight and Density it is now time to talk about consolidation when it comes to shipping. Consolidation occurs when freight forwarders get various sizes and shapes of cargo and build them up into ocean containers or aircraft positions to minimize volumetric weight.

Let’s look at the example below. The shipment on the left are high density packages all weighing 10 kilograms. The actual weight of 360 kg is much greater than the volumetric weight of 220 kg so the customer will pay for the actual weight of 360 kg. Now, the shipment on the right has low density boxes weighing 10 kilograms each. The actual weight is 120 kg but has a volumetric weight of 220 kg, so the customer will be charged 220 kg of volumetric weight for this shipment.

Actual Weight: 360 kg

Volumetric Weight: 220 kg

Actual Weight: 120 kg

Volumetric Weight: 220 kg

Freight forwarders will always measure each individual box and charge the shipper for volumetric weight wherever they can. Then the freight forwarders will mix and match the high density shipments with the low density shipments to offset each other. The result is a palletized shipment that is approximately normal density so the forwarder can profit from charging shippers for the volumetric weight, but do not pay the ocean or airline carriers for volumetric weight.

See the example below:

By mixing high density and low density boxes together the shipment is built on a pallet that has an actual weight of 240 kg and a volumetric weight of 220 kg. So the forwarder will be charged for 240 kgs and will not pay any volumetric weight charges by the carrier.

Actual Weight: 240 kg

Volumetric Weight: 220 kg

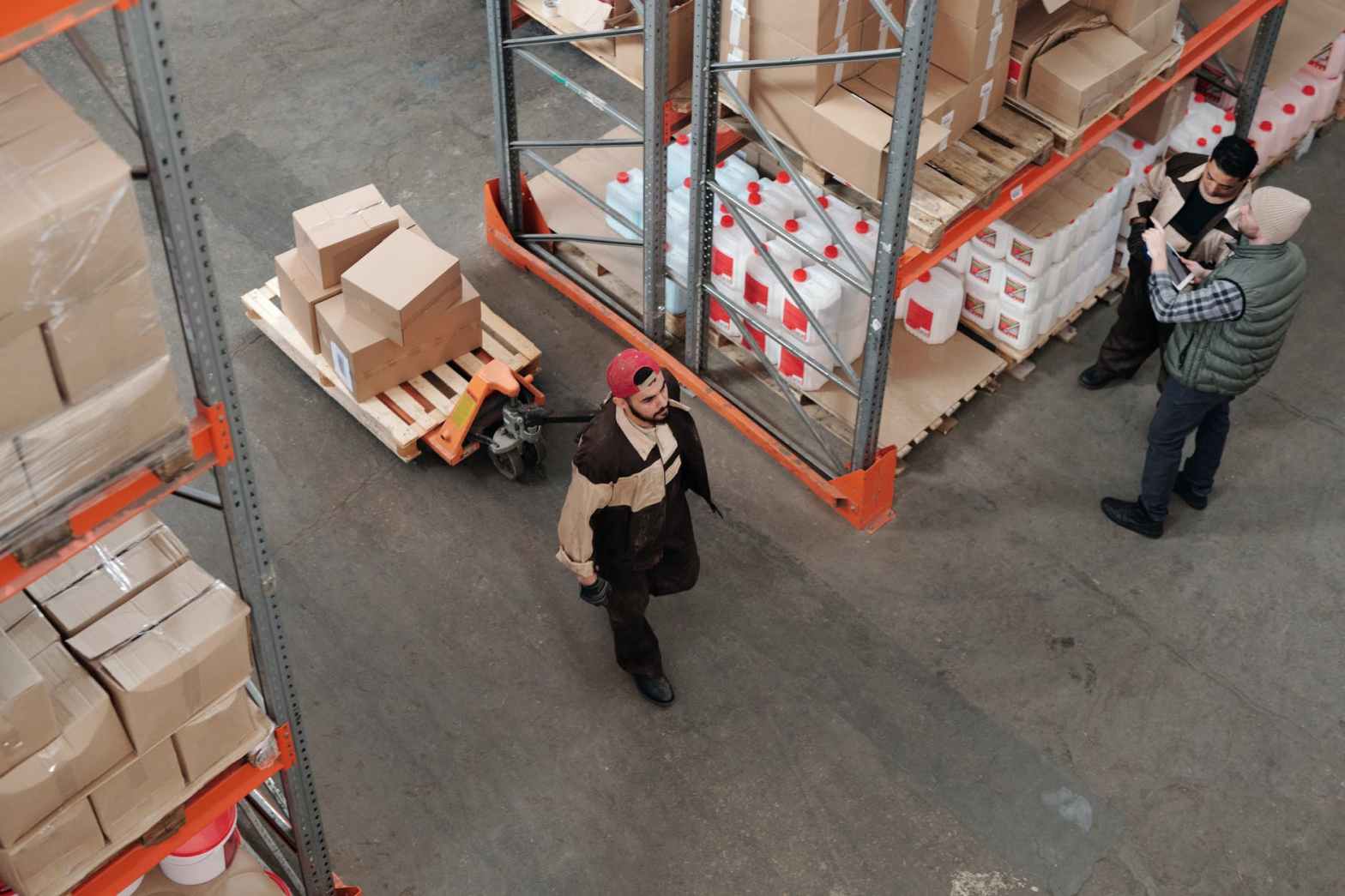

So if you are a manufacturer what can you do to save costs? The answer is to mix and match your own boxes and shrink wrap them on a pallet so each box cannot be individually measured. When tendering to a freight forwarder with a shrink wrapped pallet the forwarder will need to measure the pallet as a whole unit. See the picture below.

This will allow you to save cost and benefit from mixing high and low density boxes together to “equalize” your density.

The only condition when shrink wrapping a pallet of cargo, all of the cargo needs to go to the same destination port, whether that is an airport or an ocean port. Once it arrives it can be broken down and delivered to multiple destinations according to each label on each box.